-

Welding

- Oxycutting

-

PPE

-

Pipe tools

-

Inspection and finishing

-

Drilling

- Our news

- Good deals

-

Equipment rental

-

Need help ?

YOUR CONTACTS BY REGION

- PARIS AREA +33 1 85 41 09 13

- WEST +33 2 85 52 90 48

- NORTH-EAST +33 3 28 65 01 08

- SOUTH +33 4 28 29 66 20

- SOUTH-WEST +33 5 35 54 96 25

-

Welding

- Oxycutting

-

PPE

-

Pipe tools

-

Inspection and finishing

-

Drilling

- Our news

- Good deals

-

Equipment rental

-

Need help ?

YOUR CONTACTS BY REGION

- PARIS AREA +33 1 85 41 09 13

- WEST +33 2 85 52 90 48

- NORTH-EAST +33 3 28 65 01 08

- SOUTH +33 4 28 29 66 20

- SOUTH-WEST +33 5 35 54 96 25

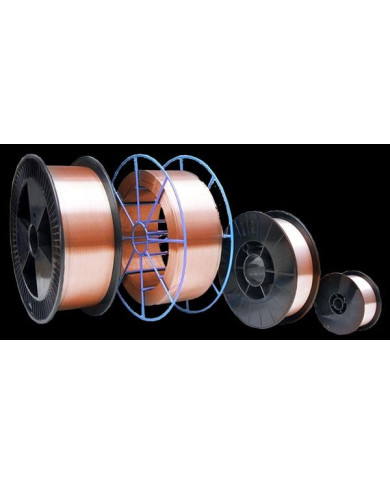

MIG, MAG welding

A solution for all budgets: we work closely with 3 trusted brands tested by us over the years. For our MIG/MAG production welding machines, Kemppi (2 year parts and labour warranty) and E.W.M. (3 year warranty) are the heavyweight equipment suppliers, whose quality and robustness are recognized all over the world. The MinarcMig Evo 200, Kempact and Fastmig ranges from Kemppi and the PicoMig and Phoenix ranges from E.W.M need no introduction. For a more affordable range, we offer the Easyweld ProMig and EasyMig ranges which are suitable for occasional to moderate use. Full after-sales service provided by us for all 3 brands. Delivery throughout Europe.

Price

€0.00 - €5,511.00

Brand

Supply current

Use

Welding intensity

Torch consumables

Equipment for welding machines

Aide au soudage

Wire type

Torch type

Matériau à souder

Type de gaz